- Tie Rod End

- Tie Rod End For Isuzu

- Tie Rod End For Hino

- Tie Rod End For Nissan Ud

- Tie Rod End For Mercedes Benz

- Tie Rod End For Volvo

- Tie Rod End For Scania

- Tie Rod End For Renault

- Tie Rod End For Iveco

- Tie Rod End For Foton

- Tie Rod End For Shacman

- Tie Rod End For Faw

- Steering Knuckle Arm For Isuzu

- Wheel Rim Clamps

- Wheel Rim Clamps For Volvo

- Wheel Rim Clamps For Scania

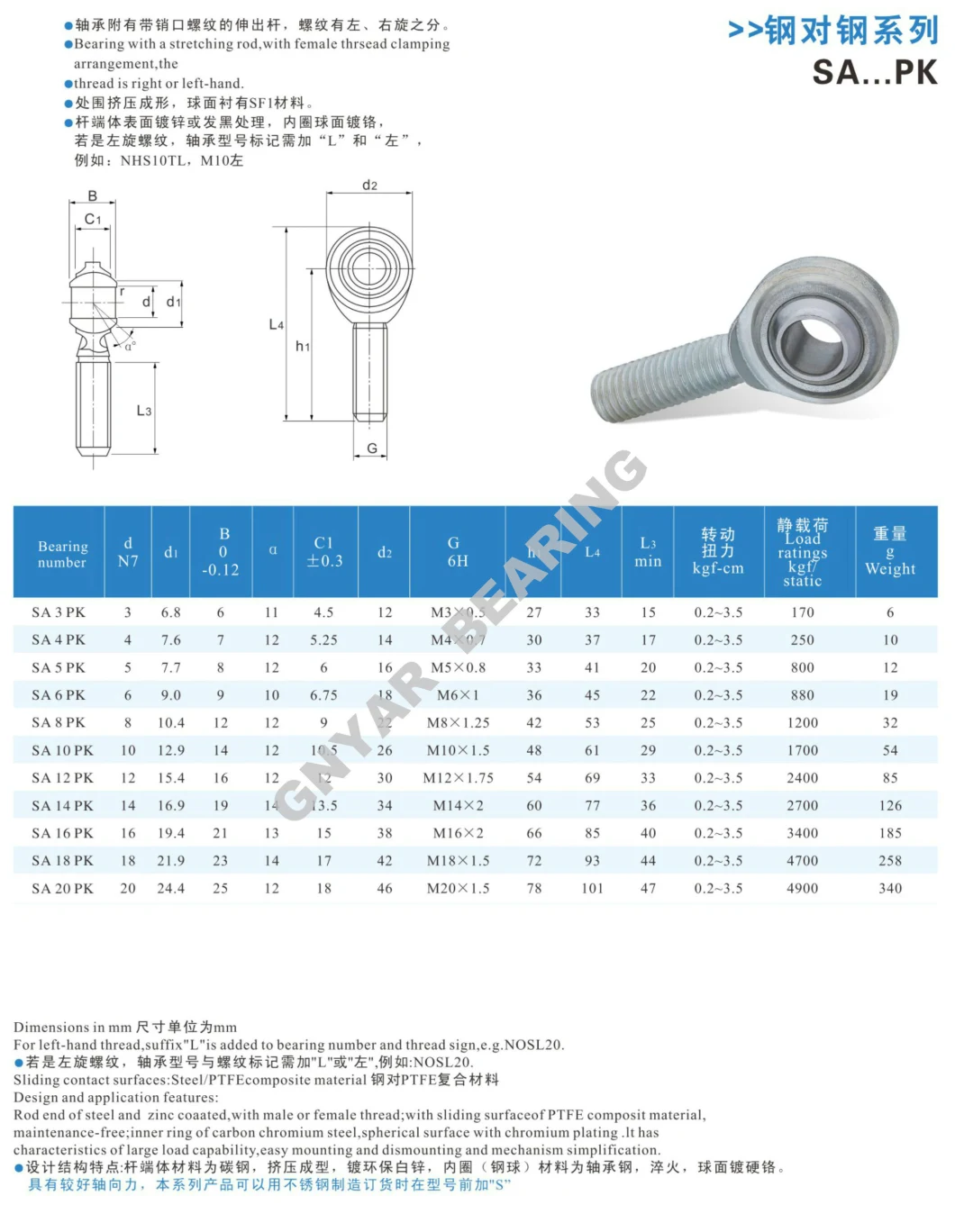

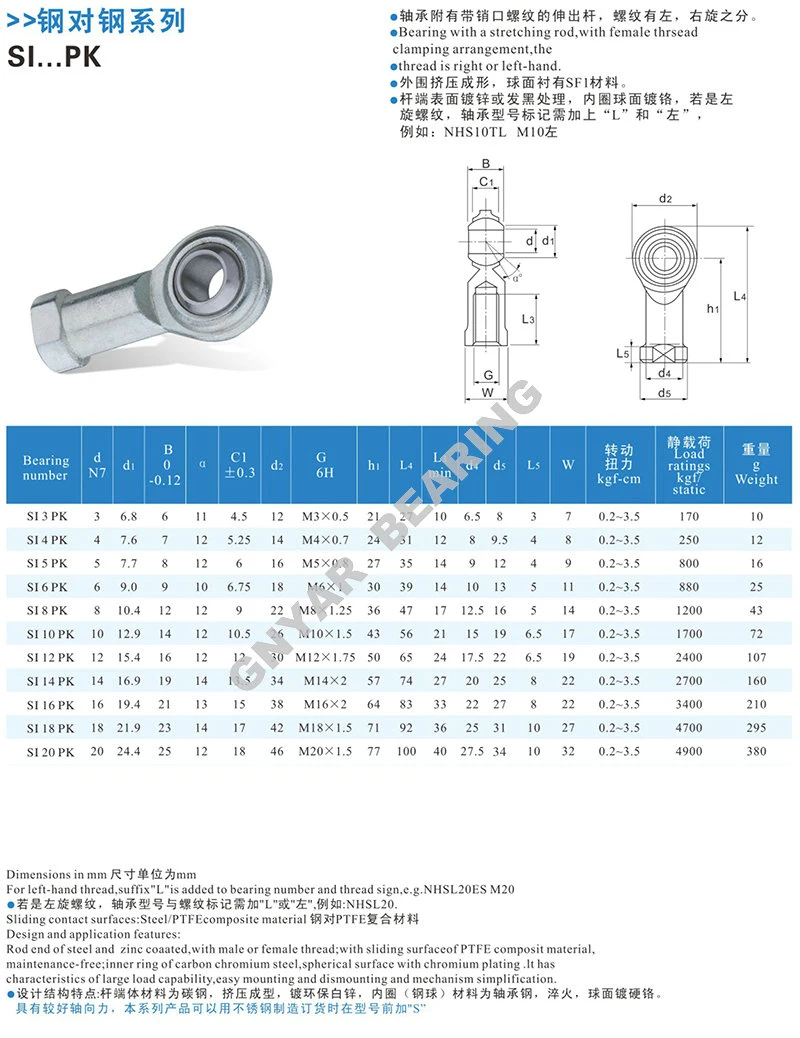

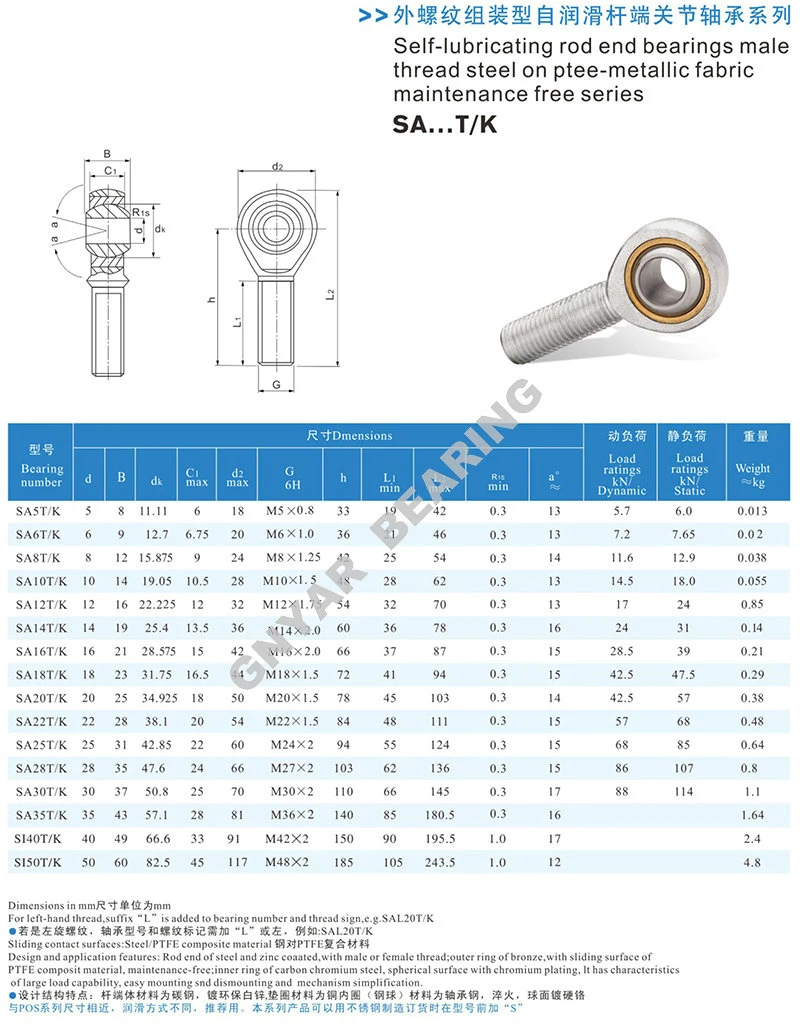

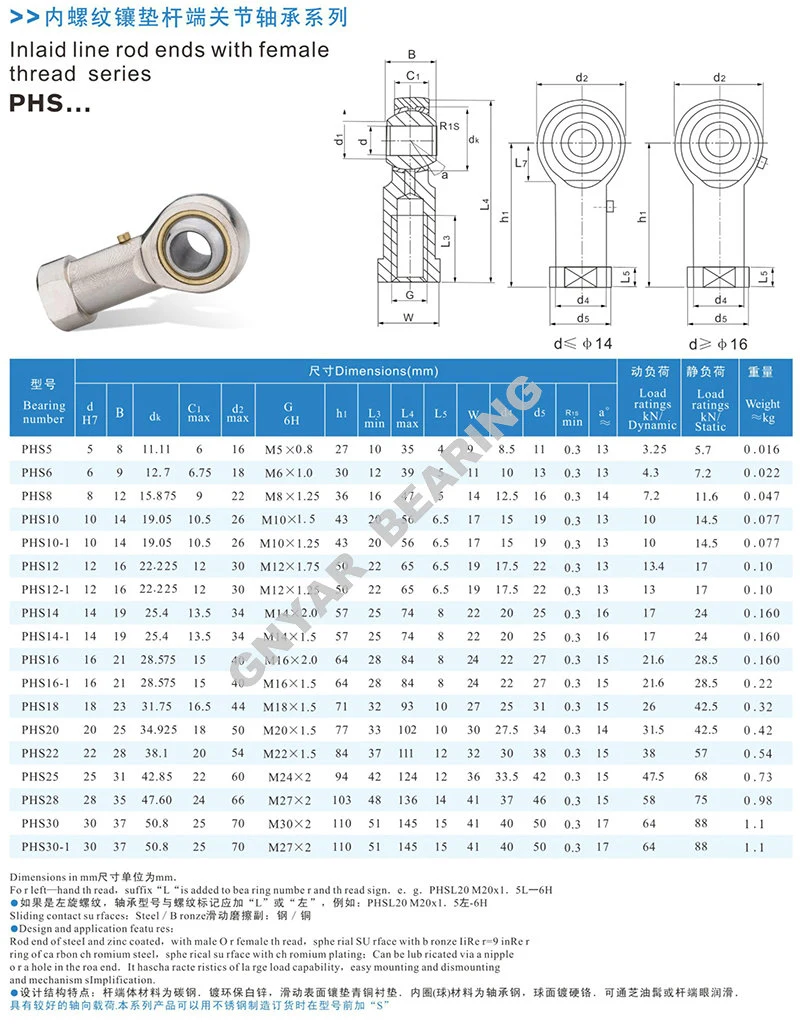

Adjustable Ball Joint Rod Ends Phs POS NHS Series Tie Rod End for Volvo Truck

Basic Info

| Rod End | General |

| Thickness | All Are Available |

| Model | Phs 8r |

| Application | Engineering Hydraulic Cylinder, Forging Machine, Construction Machinery, Automation Equipment, Automobile Shock Absorber, Water Conservancy Machinery |

| L or R | Both Are Available |

| Transport Package | Industrial Packing |

| Specification | PHS8 R |

| Trademark | GNYAR or OEM |

| Origin | China |

| HS Code | 8482109000 |

| Production Capacity | 1200000PCS a Month |

Product Description

| Materials | Series |

| Bearing steel | (PHS POS SQ SA SI SSR SQ SQZ GEEW GEES |

| Stainless steel | (PHS POS SQ SA SI SSR SQ SQZ GEEW GEES |

Price is very competitive,Quality is stable. pls inquiry.FAQ

Q: Where to find Other bearings ?

Discover the Homepage-----> Products

Q: HOW TO CHOOSE A BEARING?

To properly choose a ball bearing, the important thing is to take into account several parameters:

1. Its application

Bearings are everywhere and therefore their applications are varied:

- - Agriculture (agricultural machinery, tools, ...)

- - Domestic (turntable, fishing rod, rollers, ...)

- - Industry (assembly lines, industrial machinery, ...)

- - Machines (tools, robots, ...)

- - Vehicles (cars, motorcycles, bicycles, trailers, ...)

- - Office (fans, ….)

The application for which the bearing will be used will therefore be decisive in the choice of the part.

2. The speed of rotation

The ball bearing supports high speeds and reduced loads, while the tapered roller bearing supports higher loads but lower speeds.

The speed limits of a bearing are determined by the operating temperature.

The speed limit can be defined as the highest rotational speed a ride can achieve depending on use, without compromising performance and duration.

The speed limit of bearings depends on several factors, such as: bearing type, load size, tolerance class, cage configuration, work set, lubricant, lubrication and cooling conditions, etc.

3. The supported load

2 types of loads are supported by bearings:

- Basic Dynamic Load

This is the maximum permissible load of the bearing capable of providing a nominal service life equal to 1 million revolutions.

It is necessary to calculate the service time necessary to show signs of fatigue on the materials, and on this basis to determine the theoretical duration.

- Static charge

This is the load that applies to the stationary bearing. It corresponds to a contact stress calculated between the rolling body in the most loaded contact and the raceway.

The loads are of simple type and radial, for the radial bearings, of simple type and axial, for

the abutments.

4 Life of bearings

Bearing life is defined as the number of revolutions or hours of operation, which the bearing is able to withstand before signs of fatigue appear on one of the rings, on the raceway or on the rolling elements.

5. Nominal fatigue life

The rated fatigue life of an identical bearing or batch of bearings operating under the same service conditions shall be equivalent to at least a 90 degree of reliability.

The average life of a bearing lot is much greater than its nominal duration.

The nominal fatigue life is expressed as L10 (Million revolutions) or L10h (service hour).

6. Bearing tolerance

Bearing tolerances have been standardized both nationally and internationally in accordance with ISO standards.

Bearings are generally manufactured in the P0 tolerance class.

Other parameters can be studied to choose the bearing best adapted to your needs:

- - The conditions of use and the constraints

- - The requirements of duration of the machine

- - The mimics of congestion of the bearing

- - Negative factors (vibration, shock, heat, dirt, acceptable sound level, etc.)

The choice of bearing is therefore mainly dictated by the dimension and load characteristics to which the bearing is subjected.

In order to supply even more stable quality to our vast customers, we established a factory in Cixi city, Zhejiang province, China, near Ningbo and Shanghai port, which has recognized by special ISO. The various bearings we produce there have been inspected and confirmed by SGS to be RoHS compliant.

Besides we has a genuine concern about our customers' needs and desires, we believe that by establishing a mutually beneficial relationship with our customers we can both continue to grow and prosper, we wish and hope to always grant you satisfaction.

Q: HOW TO MEASURE A BEARING?

You have to change your ball bearing but do not know the model?

There is no written reference to it and you are lost?

You do not have a sliding foot?

The measurement of the bearing will allow you to find this bearing or an equivalent.

GNYARBearing helps you to take accurate measurement.

1st step: the inside diameter of the bearing (called the bore)

- A / Put your bearing on the grid as shown in the diagram, taking care to justify the inside edge.

- B / Mark the inner contour.

- C / For ease of reading, do not hesitate to draw lines to the axes and then take the measure.

And do not hesitate to contact our GNYARbearings team who will be happy to inform you by phone or email.

24hours CET : (86) 15381928152

Do you prefer that we remind you ?

Immediate and free call/email back

2nd step: the outside diameter of the bearing

- A / Put your bearing on the grid as shown in the diagram.

- B / Mark the outline of the outer ring. For more convenience, use a pencil with a fine point.

- C / For ease of reading, do not hesitate to draw lines to the axes and then take the measurement.

3rd step: the thickness of the bearing

- A / In the same way as for the outer diameter and the bore, place your bearing on the edge on the grid as shown in the diagram.

- B / Draw the outer contour.

- C / For ease of reading, do not hesitate to draw lines to the axes and then take the measurement.

Conclusion :

You now have 3 measuring elements that will allow you to identify your bearing: the inside diameter (or bore), the outside diameter, and the thickness.

You can postpone these measurements in our bearing search tool on our website

https://cxzybearing.en.made-in-china.com

You search, we find !